The V-belt and Its Important Role in Vehicles

It’s quite interesting that when it comes to cars, some car parts and components are often unnoticed or even taken for granted despite the big role they play in ensuring that vehicles function and run smoothly. One of the unsung heroes of car engineering is none other than the V-belt.

Despite their seemingly simple and plain appearance, V-belts happen to be some of the indispensable elements that power different key systems in cars.

From driving the alternator to spinning the water pump, V-belts coordinate the movement of the different components in silence. These belts ensure optimal performance and functionality of your car.

In this short guide, you will be stepping into the world of automobile V-belts. Brace yourself as you explore their design, functions, maintenance, and significance in modern automotive technology.

Table of Contents

Understanding the V-Belt

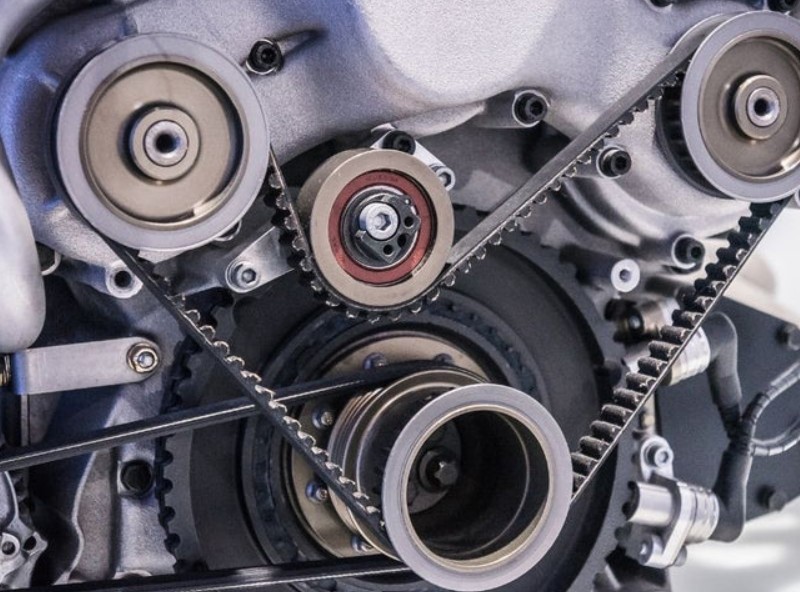

Also referred to as drive belts or fan belts, V-belts are a loop of flexible materials often made of rubber that is reinforced with cords of some synthetic materials such as aramid or polyester fibers. The name of these belts is inspired by their cross-sectional shape that looks like the letter “V.”

The unique design is responsible for helping the belt get a tight grip on the pulleys. This will then create an efficient transmission of the rotational force from the crankshaft of the engine to the different accessories. These include the water pump, air conditioning compressor, power steering pump, and alternator.

Functions and Applications of V-belts

The main function of V-belts in cars is to transfer the power to the peripheral components from the engine to enable them to carry out their respective individual tasks.

The alternator, for example, relies on the rotational energy that the V-belt provides to produce electricity. This will charge the battery and power up the electrical systems when the engine is still running.

On a similar note, the water pump also circulates the coolant throughout the engine to prevent overheating. Meanwhile, the power steering pump helps in steering as it applies hydraulic pressure to the steering mechanism.

Aside from these, the V-belts are also important to maintain proper climate control and cooling of the engine. The air conditioning compressor which is also driven by V-belts is responsible for pressurizing and circulating the refrigerant all over the AC system to facilitate adequate cooling of the interior of your vehicle.

V-belts may also drive other components like air pumps or superchargers in some engine configurations to enhance efficiency and performance even further.

Design and Construction of V-belts

V-belts in cars are designed and constructed with precision to endure the demanding conditions of an automotive environment.

Made up of durable rubber, the outer layer of these belts offers much-needed resistance to abrasion, wear and tear, and exposure to oils as well as other contaminants found in the engine compartment.

The reinforcing cords found in the rubber matrix boost the tensile strength of the belt and prevent elongation or stretching even under load.

The V-shaped profile of the belt has also been carefully designed to suit the corresponding grooves in the pulleys. This ensures optimal contact and transmission of power. This configuration also helps minimize slippage and maximize efficiency, even under sudden acceleration or high loads.

Maintenance and Replacement of V-belts

Sadly, even with the robust construction of a V-belt, this is still subject to degradation and wear and tear after some time. This is mostly because of different factors including friction, heat, and exposure to different environmental elements.

This is the reason why routine maintenance is critical to ensure the longevity and reliability of your car’s belt system. Aside from this, checking the V-belt on a regular basis for signs of cracking, fraying, or glazing can help identify potential issues and concerns before they get worse.

Proper tensioning of V-belts is also important to guarantee their optimal performance. If the belt is too loose, it may end up slipping on the pulleys. This can then lead to reduced efficiency or worse, it can even result in potential damage to other parts.

On the other hand, too much tension may cause premature wear and tear on the belt and its complete failure as well as that of other car parts. It is recommended to refer to the service manual of your vehicle or the guidelines that the manufacturer provided to help you determine the correct specifications and tensioning procedure.

If ever things have gotten worse and replacement becomes necessary, see to it that you choose a top-of-the-line replacement for your V-belt that will meet or even exceed the specifications of the OEM or original equipment manufacturer.

Just so you know, using improperly sized or low-quality belts might end up compromising their reliability and performance which can lead to expensive repair costs and possible safety concerns.

Important Role of V-belts in Modern Automotive Technology

In a time when car technology has been seeing rapid advancements, the humble and unassuming V-belts continue to play an important role in powering important systems in vehicles.

Even with the rise of alternative technologies such as hybrid propulsion systems and electric powertrains, a lot of internal combustion engine vehicles continue to rely on V-belts to drive important components.

Additionally, innovations in the materials used for belts, such as the use of composite reinforcements and advanced polymers, have further improved the durability, efficiency, and lifespan of V-belts. All of these contribute to improved reliability and overall performance of vehicles.

The developments in belt tensioning systems like the automatic tensioners, have also simplified the process of maintaining vehicles and optimized the tension levels of belts. This further boosts the overall operational efficiency of cars.

The Bottom Line

At the end of the day, the V-belts are a solid testament to the permanent significance of seemingly trivial parts in the world of automotive engineering.

Even with its unassuming appearance, the humble loop of rubber plays a fundamental role in powering important vehicle systems to ensure their smooth operation and reliability.

By getting a good understanding of the design, functions, maintenance, and significance of the V-belt, vehicle owners and technicians alike can appreciate the vital role they play in the modern world of cars.